Office and Lab Construction with Office Consolidation

at a Global Electron Microscope Maker

Project Background

Management determined that a lab is needed in Japan, and this project entails building an office and lab, and moving two offices into 1,231 m2 (13250 ft2) of leased space. Electron Microscopes are extremely sensitive instruments which need a tightly controlled environment, so the construction of the lab area needed to be completed to a very strict specification. Client was acquired partway through this project, which caused a few new challenges along the way.

| Project Aspect | Note |

|---|---|

| Organization Type | Electron Microscope Maker |

| Completion Date | 5 Jan 2017 |

| Team Members | 30 |

| Users | 50 |

| Project Duration | 18 months |

| Project Effort | 40 person-months |

| Sites | Tokyo x 2, Yokohama x 1 |

Challenges

- Sensitive lab instruments need a tightly-controlled environment, with regard to vibration, sound absorption, EMI, temperature and humidity among others.

- Lab engineers require data for temp, humidity and oxygen.

- Delivery of heavy lab equipment requires reinforced floor.

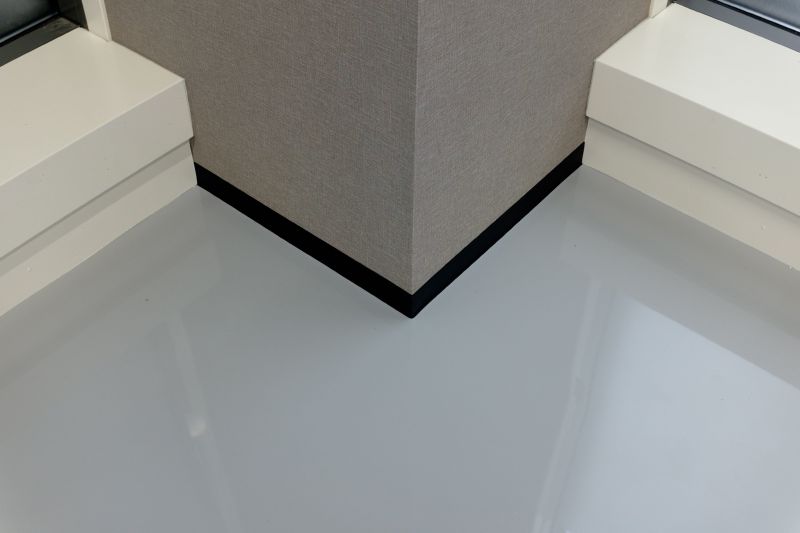

- Lab floor must be anti-static and anti-chemical in certain areas.

- Water is being piped to the tools, so there is a risk of damage from flooding.

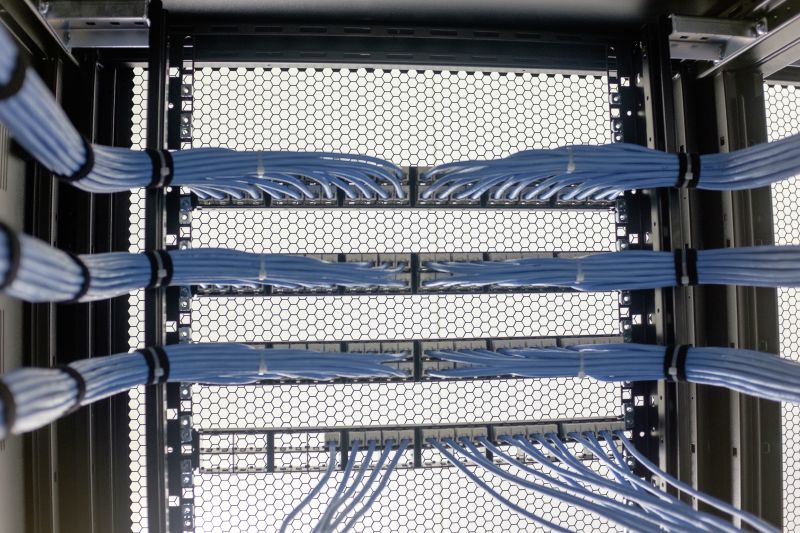

- Network cabling is physically a challenge in the lab, because of the special construction.

- New but ill-defined IT standards need to be followed.

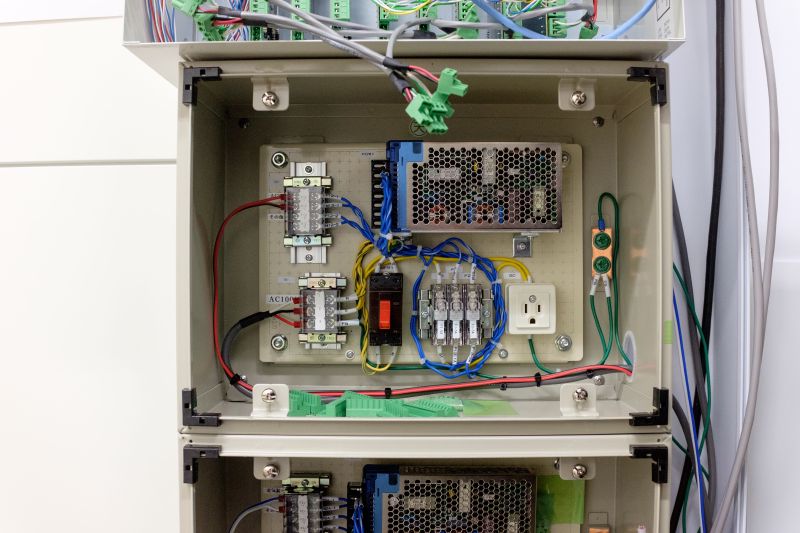

- Client standard Honeywell door security system must be connected with Panasonic building management system.

Solutions

- Tight control of building location selection to reduce vibration, strict specification of HVAC environment control in and design of lab rooms.

- Devices deployed to measure temp, humidity and oxygen, and data stored in eSolia cloud db “PROdb”.

- Floor reinforced by steel plates to allow delivery of heavy lab equipment.

- Special anti-static, anti-chemical flooring poured over concrete floor slab.

- A water “rope” is in use to shut off water flow if flooding is detected.

- New IT equipment selected to conform to future standards.

- Engineering performed to link Honeywell door security system to Panasonic building system; designed, installed, tested, operational guidelines created.

Benefits

- Final lab area is a true showcase and designed specifically to supply the environment that the electron microscopes need.

- Environment data is available to lab engineers, with periodical reports sent automatically.

- Damage is limited by auto-shutoff of water pipes, when flooding is detected.

- IT environment is modern and flexible.

- Global standard Honeywell security system is enabled, yet still linked to domestic building security system and fire alarm.

Technologies

- Special HVAC units installed to control humidity.

- EMI control equipment installed in lab rooms with most sensitive equipment.

- “Chemicrete” liquid flooring used to reduce static and allow chemical spills.

- Sensors that collect data on temp, humidity, water leakage and oxygen level.

- Cisco network and telecomm equipment.

- Honeywell door access system, with custom link to Panasonic building security system.

Request More Information

Can eSolia help your firm with a project like this? Please contact us today.